Steel Abrasives vs Silica Sand

What material is more efficient to clean or polish the surface of metal parts?

Here we tell you some details and differences about the abrasives known as "Steel Abrasive" and "Silica Sand"!

The surface treatment of metal parts is essential for future conditioning or work in the workshop. And the abrasives mentioned above can help you give them that perfect finish you need, but which of the two is better to optimize efficiency, speed, quality and cost?

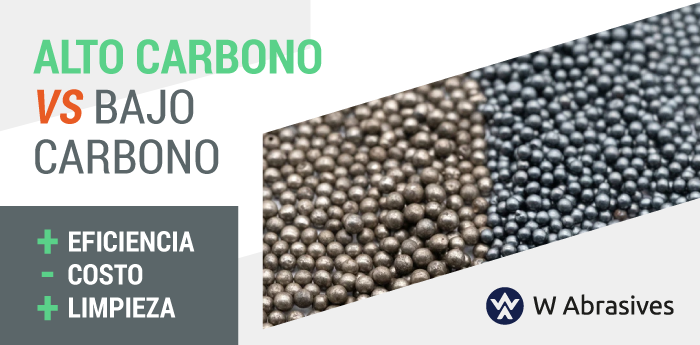

To make the best decision, you must take into account elements such as size, shape, hardness and fragility.

For example, starting with the "Silica Sand", which due to its extreme fragility and thanks to the fact that it is projected by high production equipment, can only be used once since up to 80% of the material turns into dust.