How to choose the correct abrasive for your sandblasting process?

To understand the how well, we need to understand well what is sand blast or sandblasting? The definition of this word is understood as “sand under pressure”; however, numerous abrasives in addition to sand can be used in this operation to clean, polish or remove materials and residues from different surfaces.

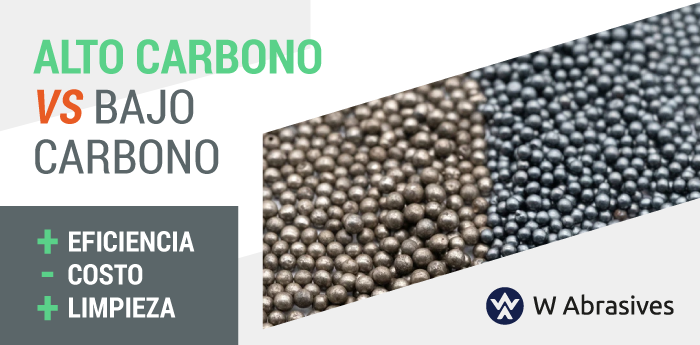

In areas of abrasives, we have 2 types commonly used:

ARTIFICIAL ABRASIVES

- Aluminum oxide

- Steel shot

- Silicium carbide

- Sodium bicarbonate

- Cut wire

- Garnet

- Copper slag

- Glass pearl

- Plastic abrasive

NATURAL ABASIVES

- Silica sand

- Diamonds

- Quartz

- Corundum

To sandblast, we use compressed air which propels the abrasives