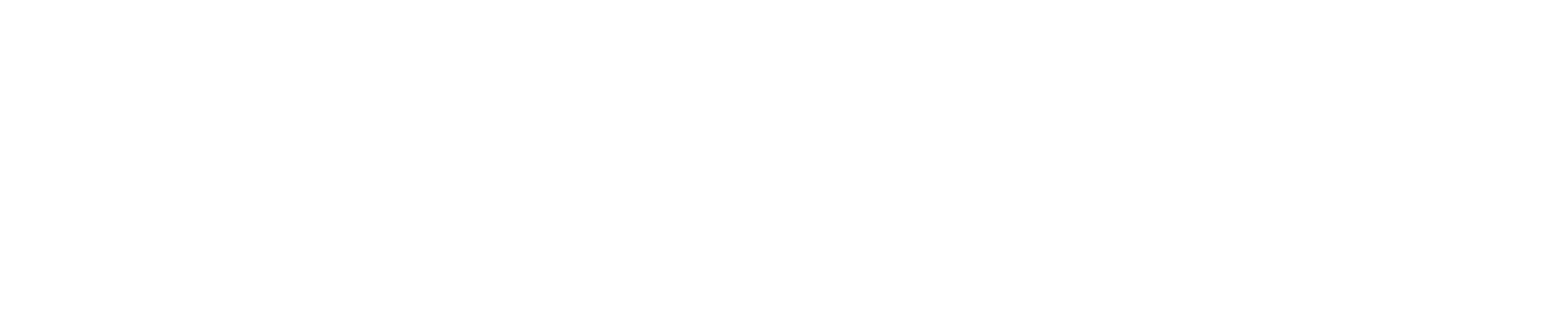

The separator is a key element of any shot blasting system. Usually it is located on top of the storage hopper, this is in charge of removing the contaminants out of the Operational Mix of shot, as well as controlling the size of the retained abrasive and disposing of material such as; very fine abrasive, contaminants removed from parts, etc. With the clean abrasive falls directly into the hopper.

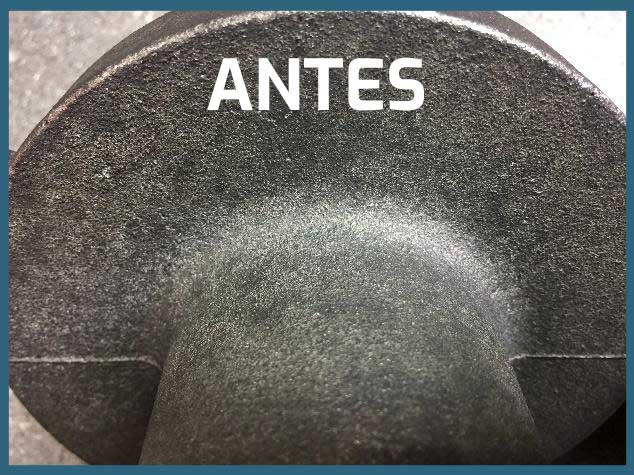

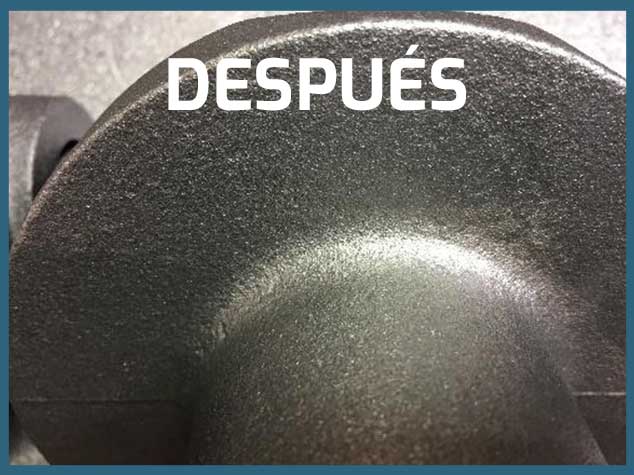

In this way, the efficiency of the separator becomes a crucial parameter in operating costs, as well as the adjustments that must be taken care of within it, such as the extraction of fines from the system and the air flow that passes through it.

Most of the separators have a rotating screen to remove large contaminants and an outlet to a container to deposit all the trash.

The design of the separator varies from machine to machine, but in all, the fundamental principle of operation is the same:

- Extend the abrasive curtain through the separator

- Regulate the fall of abrasive on the separator

- Remove contaminants from the operating mix; either through air or, a combination of air and other separators

Airflow, which removes contaminants from the operating mix, flows through the least restrictive points; So, if the abrasive curtain does not extend the full width of the separator or if there are gaps, air will flow through these gaps or thinner parts of the curtain leaving contaminants in the section of the curtain where the flow of air is lower. But also, when air flows through the gaps or thinner curtain sections, it flows at a higher velocity (creating a Venturi effect), which can cause useful size material to be removed from the Operating Mix into the air. reject container.

As the abrasive falls through the separator it is important that the fall is as vertical and uniform as possible, to achieve this, the flow of abrasive in the separator must be stopped efficiently and the shot must only fall by gravity. If the abrasive falls too fast, it may fall too far from the separator making it more difficult to clean the abrasive.

Airflow must be sufficient to remove dusts and fines from the Operating Mix. Depending on the type of separator the air flow and the separators should remove the remaining contaminants such as sand, oxides or very worn abrasive.

Our specialists highly recommend checking the spacer setting at least once a day; as well as observe in detail the extension, flow and fall of abrasive, monitor the reject container to rule out that there is useful material in it.

Get advice from the best specialists, request your services here.